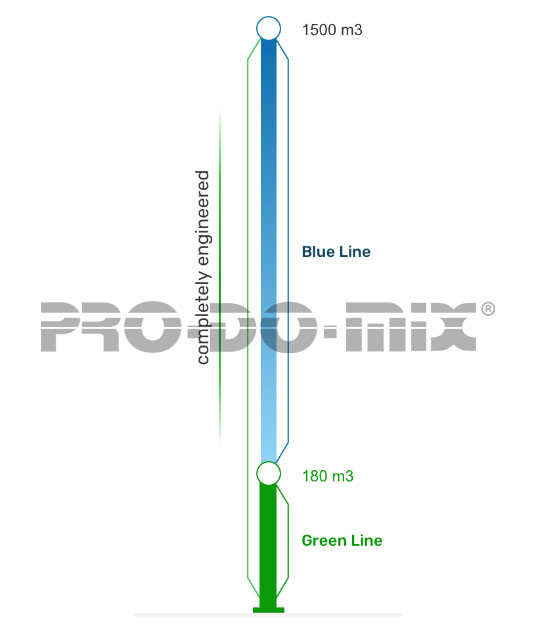

Ideal solutions for agitation fluids in tanks up to 1500 m3 with a single agitator.

From design to machining, through welding and painting, each PRO-DO-MIX® agitator is manufactured on our premises.

Following the creation of products right from the design stage allows us to adjust the motor power, shape of the impellers and speed of the machines to our customer’s needs, obtaining 100% customised solutions.

Our agitators are suitable for any type of fluid, even with very high density, up to 2.5 kg/m3 avoiding sedimentation, improving heat exchange and helping chemical reactions.

|

All PRO-DO-MIX® agitators are CE marked and this logo is branded on each machine. The technical brochure is availabe at our site: the person authorized to compile the technical file is Mr. Roberto Voltan. |

|

All PRO-DO-MIX® agitators can be produced in accordance with Directive 2014/34/EU-ATEX for installation in hazardous environments (Potentially Explosive Atmosphere).

|

|

The complete range is also TR CU certified and EAC marked, i.e. suitable for export to all member states of the East Asian Community Russia, Belarus, Kazakhstan, Armenia and Kyrgyzstan (TR CU 010, TR CU 012, ambient temperature -49/+40°C). Each product exported to one of these countries is supplied with a technical passport and IOM manual in Russian. |

Thanks to our technical expertise as well as an in-depth knowledge of mechanics and fluid-dynamics, we have developed a complete range of impellers – made with stainless steel or other high-quality materials – in order to fulfil every mixing process.

Flocculant mixing system with two-blade impeller. Thanks to its high hydrodynamic profile with wide blade surface, has the highest flow rate at the lowest peripheral speed. This design is aimed to prevent the fluid coming out from one blade to immediately meet the second blade.

Therefore, it is perfect when managing very delicate applications, where the fluid needs to be handled very gently and carefully. That is why Premium is specific for flocculation.

It can be manufactured with different diameters, 800 to 3000 mm.

A completely disassemblable option is available as well, to ease the entering through the tank manhole.

Three-blade impeller with high hydrodynamic profile. Within our industrial impeller models, it has the lowest torque for the same flow rate. Moreover, it can create the highest flow rate with the lowest peripheral speed.

It is perfect as flow-maker, for high head values in recirculation.

It can be manufactured with different diameters, 200 to 3500 mm.

A completely disassemblable option is available as well, to ease the entering through the tank manhole.

High-efficiency three-blade impeller with high hydrodynamic profile. Thanks to its high flow rate, it is particularly suitable for flash mixing, sludge and solid suspension, equalization, etc.

It can be manufactured with different diameters, 900 to 1500 mm.

A completely disassemblable option is available as well, to ease the entering through the tank manhole.

Three-blade impeller with high hydrodynamic profile. It is the “evolution” of Hurricane. Its internal velocity gradient, constant from the centre to the edge of the blade, allows the positioning of an impeller with large diameter very close to the bottom of the tank. That makes Evolution perfect for applications that require the mixer’s continuous operation during the total draw-off of the tank.

It can be manufactured with different diameters, 1650 to 3500 mm.

A completely disassemblable option is available as well, to ease the entering through the tank manhole.

Three-blade impeller with high hydrodynamic profile. Due to its special design, it can produce a centrifugal effect for which the impeller can be defined self-cleaning, thanks to this anti-clogging effect.

It is specific for nitrification/denitrification, anaerobic digestion, mixing in anoxic systems and other applications with presence of fibres.

It can be manufactured with different diameters, 1600 to 3500 mm.

A completely disassemblable option is available as well, to ease the entering through the tank manhole.

It is widely used in a broad range of applications due to its efficiency and cost-effectiveness. Within Water Treatment, pitched blade impellers are perfect for polyelectrolyte preparation and maturation, primary neutralization and pH adjustment.

It can be manufactured with different diameters, 200 to 2000 mm.

A completely disassemblable option is available as well, to ease the entering through the tank manhole.

This helical type impeller is very versatile, generally installed in fast direct mixers. Very common in small preparations of chemicals.

It is manufactured from casting in proprietary moulds.

It can be manufactured with different diameters, 90 to 160 mm diameter.

Available in 2 material options, polypropylene (PP) and stainless steel (SS 316L).

Perfect when dealing with high viscosities, cowles agitators are typically used in paints or detergents industry. Their design, combined with the high shear, allow the product dispersion and foster a quick dissolution.

They can be manufactured with different diameters, 75 to 750 mm.

Different joint options are available.

Generally used within food & beverage and cosmetics industry to manage high viscosity products or to foster heat exchange.

It is common within the pharmaceutical industry as well, in processes such as crystallization.

Moreover, it is often used as universal rotor in small tanks for multi-stage applications.

The engineering and the manufacturing of this anchor type impeller are directly related to the tank features.

Plastic mixing impeller generally used within food farming industry, for fertilization and irrigation.

It is only available 130 mm diameter.

Manufactured with white polyethylene (PE).