PRO-DO-MIX® vertical agitators are typically made of AISI304, AISI304L, AISI316, or AISI316L stainless steel. However, when certain parts of the agitator – such as the shaft and impeller – come into contact with aggressive chemicals or abrasive liquids, it may be necessary to use specific materials and coatings to preserve their durability and functionality. The choice of material and coating depends on various factors: primarily the fluid’s characteristics, but also the operating conditions of the plant.

Corrosion can occur in the presence of aggressive chemicals, a very common situation in the chemical and plastics industries, and manifests in various forms, durations, and intensities depending on the substance and temperature. An important parameter to consider when selecting materials and/or coatings is the corrosion allowance, meaning the increase in component thickness to compensate for that “consumed” due to corrosive phenomena, measured in mm/year.

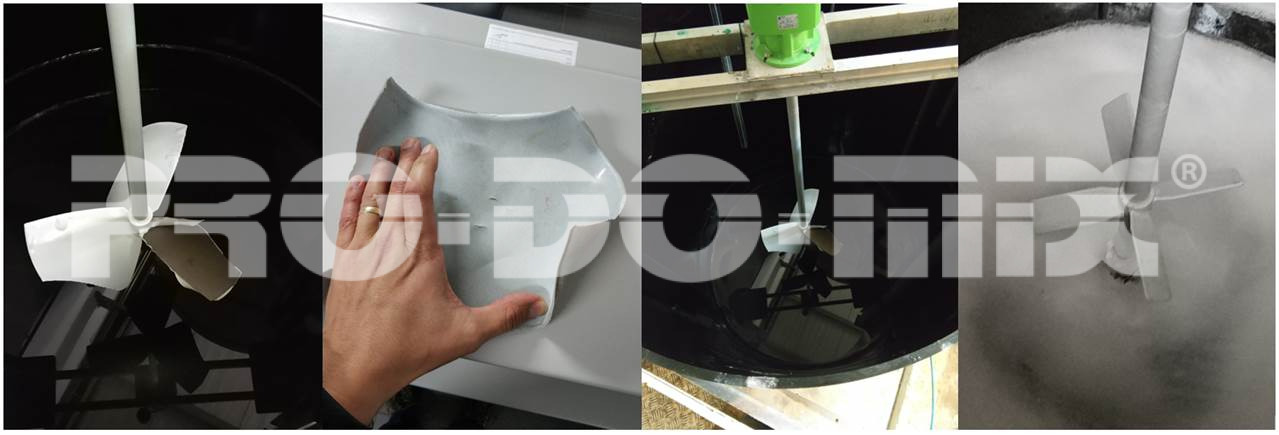

Among the possible solutions offered by PRO-DO-MIX®, there are the following plastic coatings:

| • Polypropylene, PP | • Polyvinyl chloride, PVC | • ECTFE, Halar® with chemical compatibility similar to PVDF and PTFE |

| • Abcite® | • Ebonite | • SÄKAPHEN® |

Another solution is the use of exotic materials for components in contact with the liquid. Alloys such as Duplex (with a PREN range between 28–38, EN 1.4462 / DUPLEX UNS S31803 / F51 / UNS S32205 / F60) and Super-Duplex (with a PREN range between 38–45, EN 1.4410 / SUPER DUPLEX UNS S32750 / F53 / 2507) boast high corrosion resistance and can withstand extreme environments such as high temperatures. In addition to their exceptional chemical performance, they also provide excellent mechanical strength.

By selecting appropriate materials and coatings, PRO-DO-MIX® can eliminate the risk of corrosion and ensure long-term reliability. With over 20 years of experience, we have developed a free tool for evaluating compatibility between construction materials, coating options, and the chemical substance present in the liquid to be mixed.

Abrasion occurs when the agitator is immersed in slurries or liquids containing high amounts of processing residues, such as iron, steel, sand, and other metal particles. The solid particles in the liquid generate friction, causing abrasion and damage to the shaft and/or impeller. The solution in this case is to coat the contact parts with suitable anti-abrasion materials to extend the agitator’s life and maintain its performance over time, while avoiding contamination by unwanted residues. EBONITE is considered the best coating for these applications due to its outstanding resistance to abrasive phenomena.

Abrasion is a constant risk in industrial wastewater treatment or in the mining, ceramics, and cement industries. You can explore a specific case of EBONITE application in a wastewater recovery plant in a steel mill by reading our success story.

Choosing the right coating is not enough: it must also be applied and handled with expertise. For this reason, PRO-DO-MIX® subjects all coatings to a dielectric test, ensuring their continuity and preventing possible future damage that could compromise agitator performance. At PRO-DO-MIX®, we also pay great attention to workplace safety: all our coatings are available on request for ATEX environments, using specific materials with antistatic properties.

And that’s not all. If not transported properly, an agitator can suffer damage that may not be visible during a simple inspection. For this reason, we also pay the utmost attention to transportation, using packaging such as wooden crates or cages to guarantee quality and reliability for our customers.

Looking for a way to protect your agitators from abrasion and corrosion? Contact us to find the most suitable solution for you.

Questa girante, anche detta turbina, viene usata in un’ampia gamma di applicazioni grazie alla sua efficienza e i relativi costi-benefici. Ad esempio, nel trattamento delle acque, le turbine a pala inclinata sono perfette per la preparazione del polielettrolita, per la neutralizzazione primaria e per la correzione del pH.

Caratteristiche

Diametri disponibili da 200 a 2000 mm

Disponibile una versione smontabile in 2 e 4 parti

Girante a tre pale con un alto profilo idrodinamico: girante industriale con il più basso indice di potenza in proporzione all’indice di portata. Producendo quindi la più alta portata alla minor velocità periferica, è perfetta per creare grandi volumi di ricircolo.

Caratteristiche

Diametri disponibili da 200 a 3500 mm

Disponibile una versione smontabile in 3 parti

Girante ad alta efficienza con un alto profilo idrodinamico, conosciuto anche come hydrofoil: con il suo alto indice di portata, è particolarmente indicata per il flash mixing, la sospensione di fanghi e solidi, l’equalizzazione.

Caratteristiche

Diametri disponibili da 900 a 1500 mm

Disponibile una versione smontabile in 3 parti

"*" indicates required fields