Clarification is a physico-chemical process used for water purification and making it safe for drinking. The clarification treatment, which takes place with the help of coagulants and low-speed vertical agitators, is indispensable in water purification plants, or drinking water plants. It enables the precipitation of non-settleable suspended substances in water by forming larger and heavier aggregates.

In the case of the Riyadh plant in Saudi Arabia, the client needed to modernize its old clarifier, built in the 1970s and equipped with an outdated drive unit, with a state-of-the-art clarifier or accelator. The Riyadh drinking water plant extracts water from aquifers hundreds of meters deep and transforms it into potable water through mechanical, chemical, physical, and disinfection processes.

Clarification involves large volumes of water and must be slow to avoid turbulence in the liquids. This ensures the gradual thickening and enlargement of flocs, preventing them from settling to the bottom of the tank prematurely.

In order for this delicate stage to run flawlessly, it’s crucial that the tanks and agitators are custom-designed with care. In 2014, two PRO-DO-MIX® technicians conducted an on-site inspection at the Riyadh water treatment plant to assess the situation in person and offer the client the best possible solution, designed to guarantee efficiency and durability.

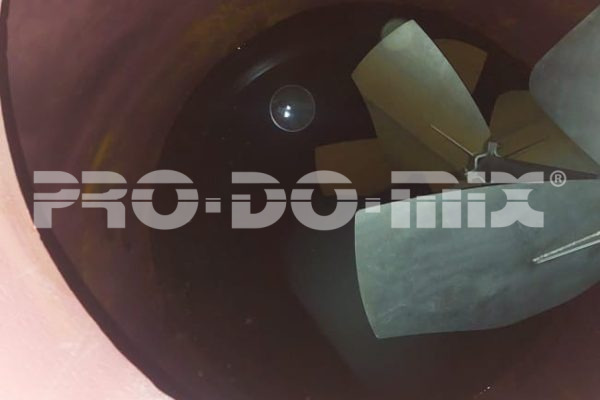

In this case, we designed and manufactured 4 special vertical agitators of the GPX.A5351.Q.285/PSXBY model, each with 15 kW of installed power, using heavy-duty bevel gear reducers and variable-speed drives (VSD). The VSD, managed directly from the electrical panel for greater convenience, allows for speed variation from 5 to 10 rpm. These is a low speed, but with significant liquid volumes, so even minor changes have an effect on fluid behavior. The impeller has a diameter of 3,400 mm, allowing for the movement of large quantities of liquid.

Furthermore, all components in contact with the liquid were made by SS 304L stainless steel, known for its excellent corrosion resistance.

The success of this project was made possible thanks to our local distributor, GHADEER TECHNOLOGY FOR TRADING EST., which assisted us in the design, construction, installation, and commissioning of the new agitators.

If you are looking for a customized solution for clarification in water purification plants, you can rely on PRO-DO-MIX®’s experience and successful cases.

Contact us now for the clarifier or accelator for your drinking water plant.