Coal-fired power plants use and need to purify considerable amounts of water. Our client, which operates the Ptolemais coal-fired power plant in Greece, approached us for a complete supply of agitators to serve the entire water purification process. It was no simple task that required experience and sensitivity in design and reliability in manufacturing.

The Ptolemais coal-fired power plant houses several treatment and purification tanks that needed customized solutions. Specifically, the purification plant consisted of a 40m3 coagulation tank, a 500m3 flocculation tank, and eight neutralization tanks.

The PRO-DO-MIX team then designed and provided the client with all the technical solutions needed to make the purification process more efficient, optimizing costs – for product supply and energy consumption – and results.

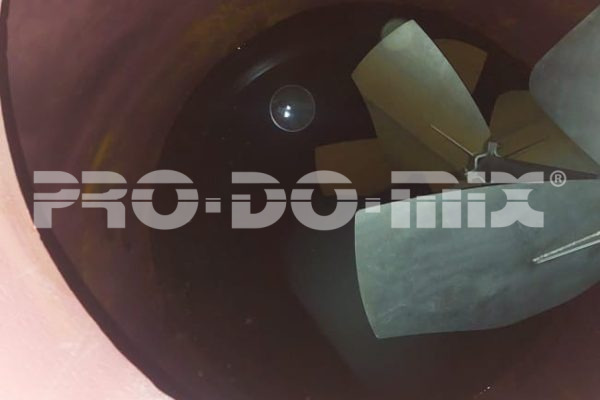

We produced 10 vertical agitators for the coal power plant’s purification system and the polyelectrolyte preparation unit with VG100 powder feeder and ACP agitators, serving the flocculation tank. Flocculation is crucial in wastewater treatment because it separates solids from water. The polyelectrolyte preparer and dispenser allows for the preparation, maturation and storage of the polymer, which, when ready, is dispensed into the flocculation tank.

Vertical agitators with impellers specifically for the industrial wastewater sector, such as the 2PM-0650 PREMIUM, 3PM-0030 EVOLUTION and 4PBT45°, were used in the project. We painted control units in accordance with the C5-M procedure, carried out entirely within our facility to ensure better quality control and process efficiency. This procedure, now an essential quality standard in our industry, is highly recommended in chemically aggressive environments and locations near the sea.

If you are looking for a customized solution in industrial wastewater treatment and purification, you can rely on PRO-DO-MIX’s experience and successful cases.

Girante a due pale studiata per la flocculazione: il suo profilo idrodinamico con due ampie pale, garantisce un’ampia portata con una bassa velocità periferica. Questo design fa sì che il liquido movimentato da una pala non incontri immediatamente l’altra.

La girante Premium è stata studiata per applicazioni delicate, nelle quali il fluido necessita di un trattamento delicato.

Caratteristiche

Diametri disponibili da 800 a 3000 mm

Disponibile una versione smontabile in 2 parti.

Il gradiente di velocità interno della girante Evolution è costante dal centro fino all’esterno della pala.

Questo tipo di girante permette l’installazione di una girante con un grande diametro molto vicino al fondo del serbatoio.

Questo rende Evolution perfetta per applicazioni che richiedano un funzionamento in continuo dell’agitatore, anche durante lo svuotamento del serbatoio.

Caratteristiche

Diametri disponibili da 1650 a 3500 mm

Disponibile una versione smontabile in 3 parti

Questa girante, anche detta turbina, viene usata in un’ampia gamma di applicazioni grazie alla sua efficienza e i relativi costi-benefici. Ad esempio, nel trattamento delle acque, le turbine a pala inclinata sono perfette per la preparazione del polielettrolita, per la neutralizzazione primaria e per la correzione del pH.

Caratteristiche

Diametri disponibili da 200 a 2000 mm

Disponibile una versione smontabile in 2 e 4 parti