Sodium silicate (Na2O3Si) is a chemical compound used in various industries, from textile to construction. Its production process involves the use of chemical reactors. A chemical reactor is a tank designed for chemical reactions, which can be either continuous – as in our case – or batch-based. In such a reactor, controlling thermal conditions and ensuring perfect mixing of reagents is crucial to achieve optimal heat exchange.

Our client, an Italian glass manufacturing company, contacted us because they needed a mixer to blend and homogenize sodium silicate in their temperature-controlled chemical reactor.

The customer’s reactor is a cylindrical carbon steel tank with an elliptical roof and bottom, diameter 2.9 m, height 3.2 m, and heating coil capable of raising the contents to a temperature of 100°C.

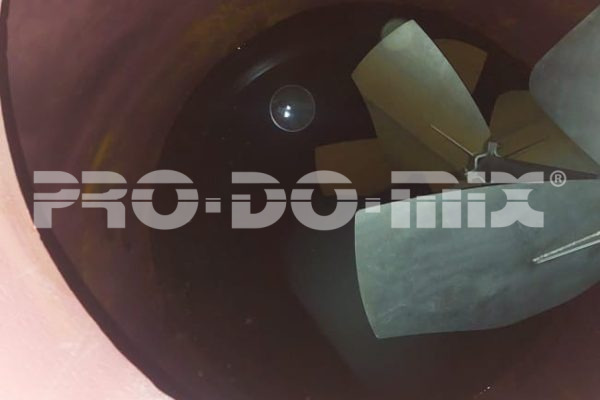

PRO-DO-MIX® designed a special GHL mixer with a 7.5 kW electric motor and orthogonal shaft reducer, ideal for continuous operation. The mixer features a mechanical seal, also known as a stuffing box, with internal cooling and a pressure valve – crucial for installations like this one where the seal’s reliability is paramount.

Another feature that simplifies maintenance and improves efficiency is that the stuffing box is removable without disassembling the shaft, resulting in significant time savings during maintenance.

We chose two high-efficiency 3PM-0030 EVOLUTION impellers for the reactor, which can be installed close to the tank’s bottom even with large volumes. The impellers and shaft were divided into three parts to allow entry through the tank manhole.

If you’re seeking a customized solution for your batch or continuous chemical reactor, you can count on PRO-DO-MIX’s experience and success stories.

Contact us now for a supply of vertical agitators and solutions for your batch or continuous chemical reactor

Il gradiente di velocità interno della girante Evolution è costante dal centro fino all’esterno della pala.

Questo tipo di girante permette l’installazione di una girante con un grande diametro molto vicino al fondo del serbatoio.

Questo rende Evolution perfetta per applicazioni che richiedano un funzionamento in continuo dell’agitatore, anche durante lo svuotamento del serbatoio.

Caratteristiche

Diametri disponibili da 1650 a 3500 mm

Disponibile una versione smontabile in 3 parti