Primary flocculation is a physico-chemical process in which the particles to be removed from the water agglomerate into larger masses called flocs, to be separated from the liquid through settling and precipitation at the bottom. Flocculation is crucial in the purification of water.

This delicate process takes place by adding a polymer solution to the tanks, which, once mixed, allows the formation and thickening of insoluble floc particles with a high specific weight. The formed flocs are very fragile and need to be gently agitated to prevent them from breaking. At PRO-DO-MIX®, we have long experience in designing and manufacturing impellers and agitators specifically for flocculation.

Today, we look at the successful case of a municipal water purification plant in Coatzintla, Mexico: the customer needed 4 agitators for four 65 m3 cement tanks.

For our customer’s plant in Mexico, we chose the PRO-DO-MIX® vertical agitator model GCR.15202.Q.440, with a power of 1.5 kW. The agitator’s speed can be manually adjusted from 5 to 20 RPM, using a mechanical variator. Thanks to the variator, plant operators can choose the most suitable speed based on the solids concentration in the sludge, optimizing the process and avoiding any potential floc breakage issues.

In our most recent installations, we have replaced the mechanical variator with a frequency variator (an inverter) that allows automatic speed adjustment based on predefined parameters agreed upon with the customer, such as the turbidity of the treated water or the concentration of solids at the inlet.

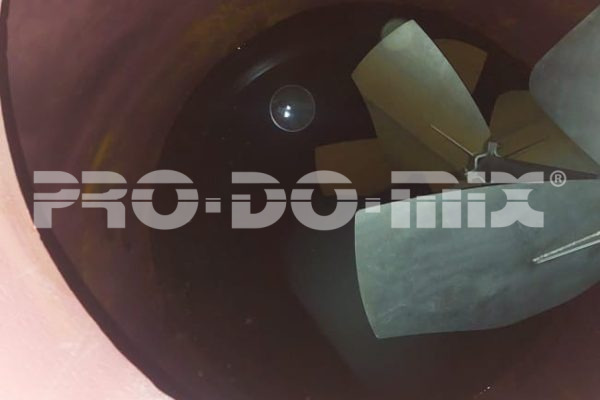

We paired each of the 4 agitators with the 2PM-0650 PREMIUM impeller, 2,000 mm in diameter, specifically designed to ensure high flow without generating turbulence in the liquid. Our impeller is perfect for applications where the fluid requires gentle treatment, especially in flocculation, as it supports the flocs and eliminates the risk of floc breakage.

Thanks to our experience in urban water treatment, purification and reuse, we have provided our customer with optimal conditions for flocculation in their water treatment plant.

If you are looking for a customized flocculation solution for urban water purification plants, you can rely on PRO-DO-MIX’s experience and success stories.

Flocculant mixing system with two-blade impeller. Thanks to its high hydrodynamic profile with wide blade surface, has the highest flow rate at the lowest peripheral speed. This design is aimed to prevent the fluid coming out from one blade to immediately meet the second blade.

Therefore, it is perfect when managing very delicate applications, where the fluid needs to be handled very gently and carefully. That is why Premium is specific for flocculation.

It can be manufactured with different diameters, 800 to 3000 mm.

A completely disassemblable option is available as well, to ease the entering through the tank manhole.